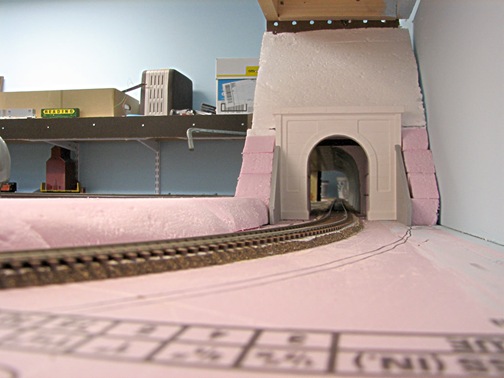

Helix Construction

I finally got a start on the helix to connect the upper and lower decks. Step one was to build the bridge that spans the doorway. A stable structure needed to be secured to the walls to support both the swing bridges for the upper and lower decks. Once that was completed, the next step was constructing the the first bridge. This bridge needed to support itself when it is swung out of the way of the entrance door. Large door hinges were used to support the bridge on one end and a small shelf attached to the layout on the other end. I added a drop down pin latch to secure the bridge when trains are running. The electrical cord in the last photo is use to connect power from the layout to the bridge.

Now that the bridge was completed work on the helix could begin. This was quite a challenge while trying to meet certain criteria. The support structure can not have legs to hold it up. We needed to be able to access the area behind the helix for storage and also storage shelves underneath. Once that was completed, I attached a temporary circle of track to test my design. THIS JUST IN: Management has decided that any further work on the helix will be suspended until a new furnace can be installed. We have had the same furnace since we purchased the house. We have also been using a swamp cooler to cool the house in the summer. The swamp cooler will be lucky to survive this season. So, we will be purchasing a new central air and furnace in the near future. It will be easier for the installers if the helix is out of the way. Stay tuned for further announcements.

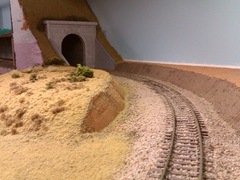

Back Drop Construction

I have been anxious to begin creating scenery for the layout. The shelf stanchions for the the upper deck create a problem for making good looking scenery. To cover these up, I will install thin hard baord to create a smooth surface for the background painting.

Experiments with the “Bullfrog”

I have been looking for a reliable and cheap method to control the turnouts. After experimenting with various homemade controls, nothing worked reliably. The Fast Tracks company (Click here to visit their website) from Canada have created a turnout control call the “Bullfrog”. It is made from laser cut model aircraft plywood. You can purchase them assembled or unassembled. These units are easy to construct and are easy to install. For the control knob, I used a large wood bead and a short length of coat hanger.

Rolling Stock Storage

I’ve needed a way to store the freight and passenger cars for the various trains I’ll run. While visiting the local Wal-mart I found these inexpensive storage boxes with drawers. They were the right height to hold cars and had room for about 8-14 cars in each drawer. The drawers were then mounted on a board with casters to make it easier to move around. I lined the drawers with Sill Foam Gasket material to protect the cars from damage.