Continuing the Journey

The six cars that are required for the Rolling Stock (Motive Power & Cars) section of the Golden Spike Award are finally finished. In this post, I’ll review the cars that I will be showing to the AP (Achievement Program) Coordinator for evaluation.

Car #1 – Ralston Purina Reefer Car

As seen in the last post this car has been updated with new grab irons, ladders, stirrup steps, roof walk, body mounted couplers, new trucks, metal wheels and weathering.

BEFORE

IN-PROGRESS

AFTER

Car #2 – Milwaukee Road TOFC Car

The car began life as a standard Blue Box Athearn 50’ flatcar. Additions to this included new metal wheels, couplers, side guard rails, collapsible trailer hitch, bridge plates, Milwaukee Road 40’ trailer and weathering.

BEFORE

AFTER

Car #3 – Milwaukee Road Snow Plow

This car started out as an International Hobby Corporation Snow Plow. I changed the the horn hook talgo trucks with regular trucks with metal wheels and body mounted Kadee couplers. In addition to the weathering, I added an LED to the headlight controlled by a switch and battery hidden under the concrete weights.

BEFORE

AFTER

Car #4 – Milwaukee Road Stock Car

I have written about this car in a previous post. Not much was done to this car except the addition of metal wheels and heavy weathering. The previous post can be viewed by clicking this link: http://northmontanaline.blogspot.com/2014/08/layout-update-29.html

BEFORE

AFTER

Car #5 – Great Northern Caboose

This caboose was a project started many years ago when the only decent looking inexpensive Great Northern caboose came from Athearn. Your choices were either brass or craftsman kits from companies like Silver Streak or Northeastern. My abilities at that time did not justify either kit and my wallet could not justify brass. The Blue Box kit seemed like the best alternative at the time. I changed things on the caboose to try and match Great Northern prototypes as best I could. The list includes sanding the roof to remove the rivets represent the tar paper roofs the GN used. The running boards were replaced as they represent the Santa Fe design that the original model takes after. New ladders were fashion from stock material to emulate the standard GN practice. Molded on grab irons were removed and replaced by wire grabs including new roof grabs made from lift rings and wire. The brake stands were replaced with a more appropriate style and end railings were replaced with GN style gates with logos and stripes. Additional reflective square decals were added along with lanterns for the rear end. New couplers and metal wheels were changed out. Window glass was added to the interior. Finally came time for weathering to give the caboose its proper well loved look.

BEFORE

AFTER

Car #6 – Milwaukee Road Log Car

This car began as an Athearn Blue Box 40’ flat car. Extensive modification has taken place to the body of the car. The floor was chopped out and replaced with shorter end pieces. a new cover over the center sill placed as well as angle stringers finished out the flooring. Piping for the brake rigging was added to the molded on brake pieces in the under frame. While not completely correct it does get the idea across. Additional steel weights were cut to size and glued into the center sill spaces. The stake pockets on the side of the car were removed and filled in with putty. The molded on grab irons were removed and new wire grabs were added. The log bunks are from Details West. Painting was done using a rattle can of Krylon red primer. Microscale decals for a box car were the closest I could find that match the prototype. The usual metal wheels, Kadee couplers and weathering completed the model. The simulated logs are branches from trees in my yard.

BEFORE

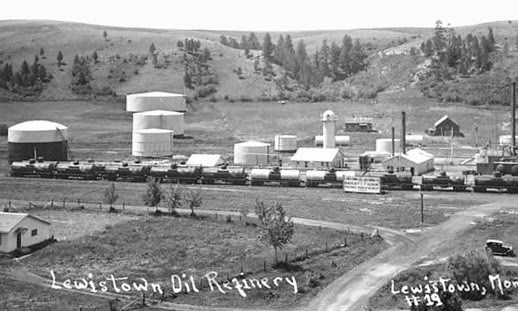

PROTOTYPE

AFTER